果蔬速凍前處理生產線

Vegetable and fruit quick-frozen pretreatment production line is an indispensable processing equipment before quick-frozen vegetable. It was developed by our company on the basis of absorbing the advantages of similar equipment at home and abroad in the early 1990s. The machine has reliable performance, low energy consumption, high efficiency, small occupied area, safe use, simple maintenance and operation, and is made of all stainless steel, fully in line with food. Hygienic standards for export of products.

It is suitable for processing taro, green bean, asparagus, spinach, cabbage, potato chips, radish chips, cauliflower and other vegetable leaves and stems, root vegetables, yellow peach, mulberry and other fruits. The processing time is 3-20 minutes.

>> Main Technical Parameters of Leaf Vegetable Quick Frozen Pretreatment Production Line

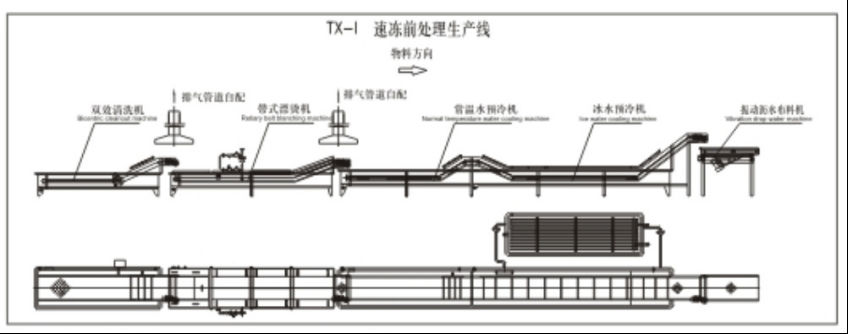

>>Sketch of quick-freezing pretreatment production line

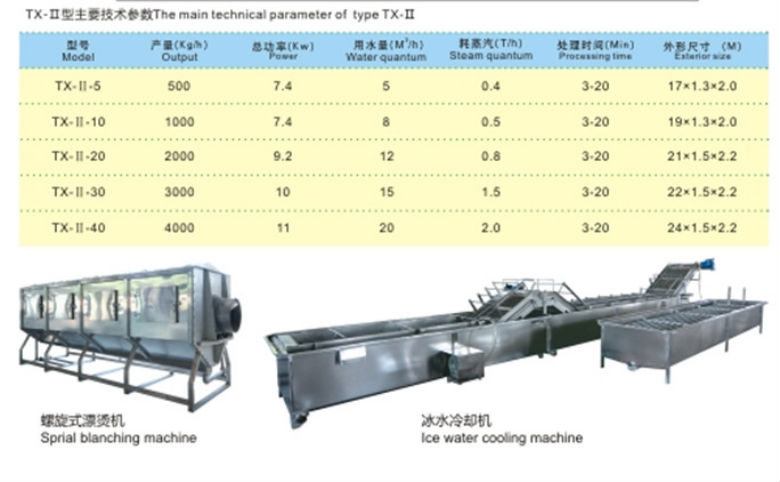

Production line for quick-freezing pretreatment of rhizomes

The production line of quick-freezing pretreatment is that spiral blanching machine is used in the blanching section of the production line, which is more suitable for processing fruit and vegetable products with small proportion and easy suspension.

>>Main Technical Parameters of Quick Frozen Pretreatment Production Line

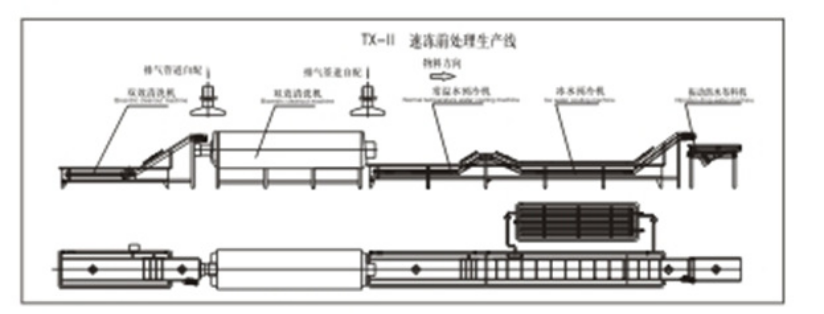

>>Sketch of quick-freezing pretreatment production line

The production line of quick-frozen fruit pretreatment is mainly composed of high-pressure cleaner, selection conveyor, bubble cleaner, screw blanching machine, room temperature cooler, ice water pre-cooler and vibration leachate machine, which realizes the automation of vegetable cleaning, sorting, blanching, cooling, pre-cooling, filtering and other quick-frozen pretreatment processes.

The main advantages of similar products at home and abroad are absorbed in the design of the production line. The blanching time and temperature of vegetables, as well as the conveying speed, can be adjusted to obtain the best treatment effect of all kinds of vegetables. The equipment runs smoothly, has reliable performance, saves energy consumption, occupies less area, is simple to use and easy to maintain. It can be used in combination, operated on a single machine, placed flexibly, and equipped with auxiliary equipment such as knives. It can completely meet the needs of green bean, asparagus, broccoli, taro, green bean, soybean, sweet corn, strawberry, cherry, etc. Production of fruit and vegetable products such as apple, onion, tomato, mushroom, pumpkin, spinach and bean sprouts. The equipment is made of stainless steel, which is easy to clean and maintain. It can completely meet the hygienic requirements of food export.